Critical factors for success in valve spring manufacturing

The manufacturing of valve springs requires high-quality, durable steel wire since the springs need to exhibit extremely high fatigue properties and good relaxation properties at increased working temperatures. Our product range, specifically the OTEVA series of oil-tempered valve spring wires, is designed to meet these challenges. They offer strength and durability that are unmatched in the industry.

Our manufacturing processes, from wire shaping to size ranges, surface finishing, and eddy-current testing, contribute to the strength, durability, and precision of our valve springs wire. We follow strict quality control procedures, with comprehensive testing and laboratory checks on all finished wire, ensuring our products consistently meet the highest standards.

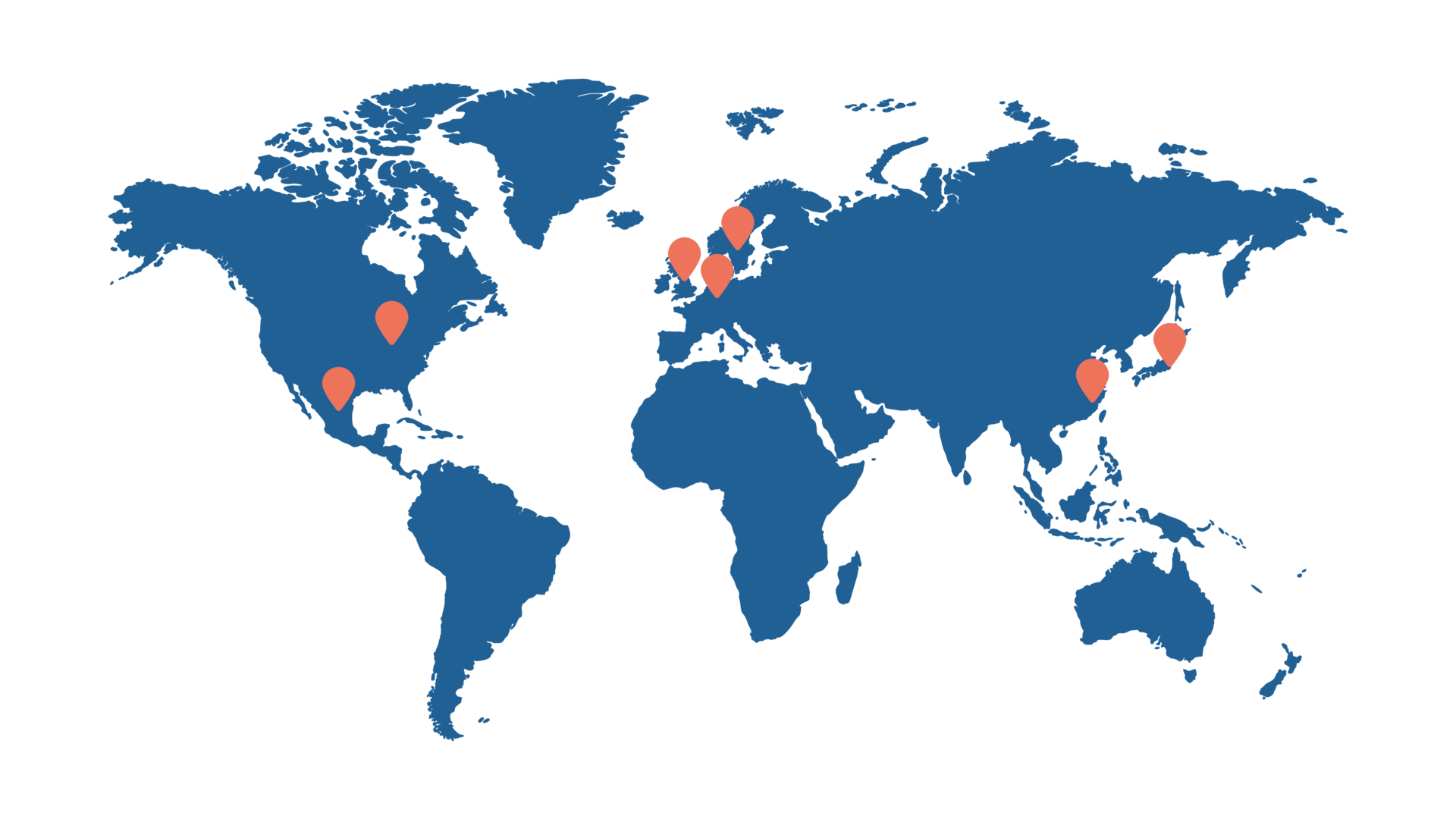

Global presence, local support

Across our entire product line, we consistently focus on quality, reliability, and adaptability. We conduct rigorous testing on each batch of wire, ensuring that they meet our high standards and the specific needs of our customers. Our global presence enables us to address local needs effectively, emphasizing our commitment to customer satisfaction.

We continue to improve our oil tempered wire products by refining our manufacturing processes and exploring new applications. This relentless pursuit of excellence is central to our mission and informs every aspect of our work.