Our year in brief 2024

Welcome to our summary of last year. We continued to develop, strengthen our position in the market and build for the future. By combining innovation with sustainability and a strong focus on our people, we navigated challenges and created opportunities.Comments from our CEO

Innovation, collaboration and transformation!

2024 has been a year when we at Suzuki Garphyttan have continued to develop. Market changes led to increased demand in China and lower volumes in Europe, which has driven the transformation especially in Garphyttan and Leeds. At the same time, our presence in both Mexico and the US provides stability in a challenging North American market. Being strong in the automotive industry is crucial, and we continue to develop quality and efficiency.

Through innovation, sustainability and a focus on our employees, we have created opportunities and navigated challenges. We reinforced the safety culture, invested in sustainable production solutions and took important steps in digitalization. 2025 will be a year of continued transformation. Despite a weak end to 2024, we see opportunities to strengthen our position and build an even better future – together.

Ad Raatgeep,

President and CEO

Highlights

2024

Collaboration and business opportunities in Düsseldorf, Germany

At the exhibition we showcased our comprehensive range of spring wire, designed for a broad spectrum of industries.

Site Leeds obtained their certification

Now all our sites are certified to ISO 14001.

Next generation hardening

Our oil and lead-free hardening was approved in China.

Billion SEK in revenue

Metric tonnes of wire produced

Years of experience

GROWTH AND DIVERSIFICATION

Strong position in automotive

Our history also includes the future. When the steel and automotive industries are in transformation, Suzuki Garphyttan is working actively to stay abreast of that change. But we won’t leave our current customers in the lurch – on the contrary. Development, in terms of both quality and efficiency, continues within the automotive segment. We want our customers to rest assured that we will still be at their side in the future.

In pace with increasing electrification, the need for traditional oil-hardened wire products is decreasing in the automotive industry. Suzuki Garphyttan is dealing with the situation in a proactive way, focusing on both new and old customers.

READ THE ARTICLE

GROWTH AND DIVERSIFICATION

A bright example of great teamwork

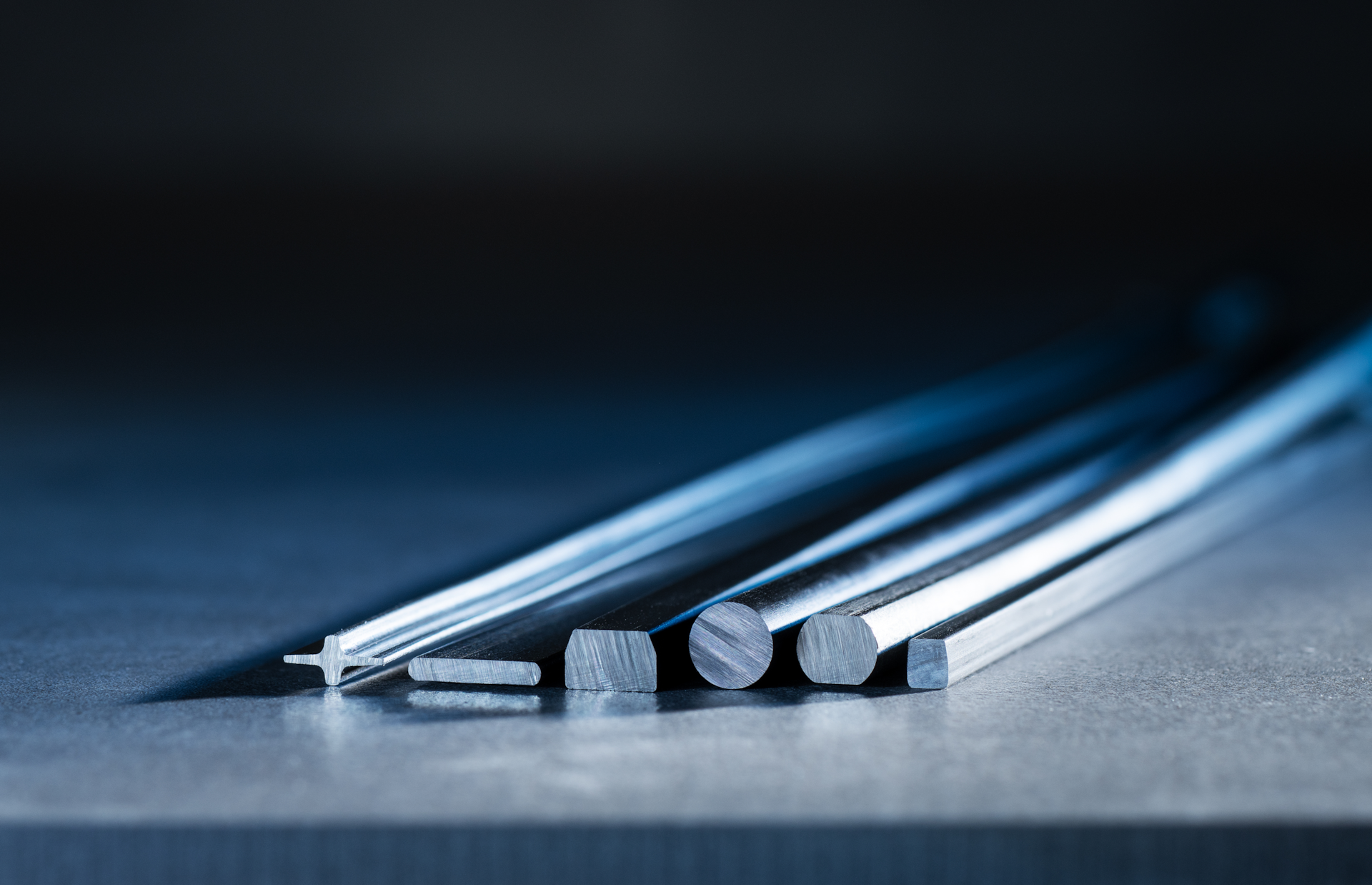

In 2024, Suzuki Garphyttan developed Bright, its new bright drawn stainless steel wire. This was accomplished by bringing together expertise in Marketing, Production, and Research & Development (R&D). However, the collaboration has not only taken place internally – the customer perspective has been included from the start.

“We have involved customers throughout the development process. We are therefore confident that our product both expands and enhances our offering,” says Ilaria Menti, Application Manager.

READ THE ARTICLE

Product news

A customer centric approach for fine size spheroidized wire products

In our ambition to transform, it is more important than ever to understand our customers. When we identified the market need for fine size spheroidized wire products, it also became clear that we had a gap in our product portfolio.

Suzuki Garphyttan decided to develop the missing product range with the first focus being on fulfilling the needs of the textile industry. Tony Farley, Sales Manager at Site Leeds combined with a responsibility for Business Development for the Suzuki Garphyttan group, was involved from the start:

"One of our existing customers required us to offer a spheroidized annealed product which was smaller than our wire drawing capability in Leeds. Site Garphyttan could meet the dimension requirement but not the batch annealing setup".

Capacity

Optimized capabilities for shaped wire products

Building on the global expansion of shaped wire capabilities in 2023, we have further advanced our development over the past year. By refining control over cleanliness and atmosphere in our processes, we are better positioned to meet customers’ expectations for mechanical properties and geometries. Our ambition is to provide a wider range of options for the visual appearance of our products.

To optimize our offering for shaped products we have been focusing on installation of respooling equipment to provide additional ways to deliver in China and USA. This way we are able to offer more sustainable production locally. Providing the same products from multiple sites also mitigates risks for our customers.

Machine design

Innovation is in our DNA

Our ambition is to not only offer the world’s best steel wire. It is also to create the best methods for manufacturing it, considering factors such as quality and environmental impact. We have had this ambition for a while now and last year we continued our efforts.

With expert knowledge and top-class equipment, we develop our own machines and machine parts to meet customers' quality requirements, strengthen competitiveness, improve workplace environments, and reduce our climate impact. When we develop our own solutions, we safeguard that we get the best for our processes. We also gain improvements that are positive for our workforce.

At Suzuki Garphyttan we produce world class steel wire. We will continue to do so, partly by taking responsibility for developing the right capabilities in our production to meet market demands today and in the future.

Voices from our organization and our collaboration partners >>> What does collaboration mean to you in your daily work, and how do you see it impacting the results?

Jonathan Chappell

Product & Project Manager, Leeds, UK

"As we strive to diversify and enter new markets, both customer and internal collaboration are essential. Working closely together allows us to fully understand each other’s demands and challenges. Together we achieve what none of us can do alone."

Per-Erik Berg

R&D Technician, Garphyttan, Sweden

"Working together is key to getting good results. To make it work, you need honesty and determination. When we team up with colleagues, other departments, and external partners, we come up with better solutions, which brings in fresh ideas and makes the work more fun and fulfilling."

Enrique Sánchez

Sales Manager, San José Iturbide, Mexico

"Sharing ideas, knowledge, and perspectives makes us stronger. Caring for each other and all stakeholders, with a team-oriented approach, drives our success. Together, we overcome challenges, deliver better solutions, and contribute to great achievements for our customers and ourselves."

Digitalization

New ways to optimize production

The digitalization process currently in progress at Suzuki Garphyttan will increase production efficiency. With sensors and advanced analyses, more optimized production comes much closer.

Lower CO2 emisions compared to 2020

Reduction of accidents compared to 2023

Participation in the global Coworker Program module 1

SUSTAINABILITY

Next generation hardening improves work environment

Our long-term ambition to reduce the environmental impact also affects the working environment. In 2024, we continued our efforts to develop the next generation hardening process at our site in China.

“It’s amazing to have a production line with no oil or lead. Our work environment has improved a lot,” says Jacky Li, who leads the hardening line at Site Suzhou.

We have begun to phase out traditional hardening with oil and lead for more environmentally friendly alternatives. The first oil- and lead-free hardening line has been in operation for two years. A second line is being installed and will be in operation early in 2025.

Accident-free by 2025

A year of great progress in safety

2024 was our safest year so far with a 75% reduction of accidents compared to 2023. Since 2018, we have used a strict definition of accidents to increase safety awareness and reporting. In 2024, we aligned this definition with industry standards to better reflect safety deviations, including accidents and near misses. This makes our results more comparable within the industry, while still keeping safety as our top priority.

We have increased our risk reporting for the fourth consecutive year, indicating a stronger safety culture and contributing to improvements in our safety efforts. Since we launched our safety initiative four years ago, accidents have decreased by 85%, and preventive reports have more than doubled.

As we move into 2025, we aim to continue strengthening risk awareness and build a work culture based on care, collaboration, and continuous improvement. Together, we are working towards an even safer future at Suzuki Garphyttan.

Life Cycle Analysis

Environmental impact of our products

We are actively working to reduce our carbon footprint and meet the sustainability requirements of our customers and society. In 2024, we initiated our first Life Cycle Analysis (LCA) to assess the environmental impact of our products from raw material extraction to delivery.

Our initial results show that the biggest climate impact comes from the wire rod, accounting for 80–90% of total emissions. Transport and our own production have a smaller impact, partly thanks to our use of fossil-free electricity.

The next step is to develop a model to analyze all our products while also incorporating more indirect emissions within our value chain (Scope 3). By combining these insights, we gain a clearer understanding of our total carbon footprint enabling us to reduce it and meet the sustainability demands of our customers and the future.

UN Global Sustainable Development Goals

We have reduced our CO2 emissions with 50 percent*

We are very proud to share that our CO2 reduction target already has been accomplished, and we are now busy with setting new goals. Our efforts will not stop. In 2020, our CO2 emissions were 1 300 kg per ton of wire produced*. Our initial goal was to reduce this to 650 kg/ton wire produced*, by 2030, a 50 % reduction.

The most important factor in reducing our carbon footprint has been to increase our use of fossil-free energy. We have switched to fossil-free electricity at several facilities and installed solar panels at our sites in Suzhou, China and San Jose Iturbide, Mexico.

* Based on emissions in scope 1 and 2 according to GHG Protocol and also scrap of wire rod in the manufacturing process.

Voices from our organization and our collaboration partners >>> What do you do to contribute to a more sustainable world?

Andrea Xia

Senior EHS Engineer, Suzhou, China

"Managing Environment, Health, & Safety (EHS) effectively strengthens a company's Environmental, Social, & Governance (ESG) performance. By prioritizing safety, environmental responsibility, and well-being, we contribute to long-term business success and sustainable development within our organization and the surrounding community."

Mika Cancino

Environmental & QA Coordinator, Garphyttan, Sweden

"Sustainability has become a key factor in business success and will remain central to our goals. At Suzuki Garphyttan, we aim to lead our industry by reducing waste, optimizing resource use, minimizing environmental impact, and promoting circular economy practices."

Hanna Escobar-Jansson

Communications Director, Jernkontoret, Stockholm, Sweden

"As a business association, Jernkontoret works to create the best possible conditions for a competitive steel industry in Sweden, where a key aspect is the conditions for transition and sustainability. Right now, the industry is undergoing a historic transformation, and I am proud to contribute to this important work."

Digitalization

Increased IT security

IT infrastructure operating around the clock is a precondition for modern industrial operations. In the past year, a new data center was brought into use to safeguard backup processes and operational reliability in our IT systems.

A GREAT PLACE TO WORK

Tribology - the science of friction, wear and lubrication

Without knowledge, development stops. With that insight as its guiding star, a course in tribology was arranged in 2024. Employees within Suzuki Garphyttan got a chance to learn more from one of Sweden’s leading authorities in the area – Professor Michael Olsson.

Tribology is the science of friction, wear and lubrication.

“Many aspects of our daily lives involve tribology,” explains Professor Michael Olsson, showing us around one of Dalarna University’s laboratories in Borlänge, Sweden.

A GREAT PLACE TO WORK

A dynamic and inclusive workplace through competence development

By investing in both technical and personal development, a stable foundation is built to meet future challenges. At Suzuki Garphyttan we focus on equipping our employees to navigate in a world characterized by change. Competence development is an investment for the future.

Our ambition is to create a workplace where people thrive and can work together to achieve common goals, regardless of where they are geographically. In today's rapidly changing business landscape, competence development is more crucial than ever to safeguard the skills needed for tomorrow. This is especially important in a global organization where employees work on different continents and come from different backgrounds.

Collaboration

A vital connection to the talents of tomorrow

At Suzuki Garphyttan, we see collaboration with various universities and organizations as an important part of our development and our commitment to society. Through these types of initiatives, we open up a way into our company, but we also contribute to research, innovation and competence development through thesis in specialist areas. We participate in trainings, share knowledge and offer internships.

We also see great value in supporting initiatives such as Tegelbruket in Örebro, Sweden. Here we work together to build relationships and open doors to employment. A road that is not always straight forward. The collaboration is a long-term commitment that means that we offer teenagers and young adults various forms of support, work-place visits, mentoring, on-the-job training, internships and employment.

As we continue to grow, we will need a wide range of skills. Bringing in people with diverse backgrounds and experiences is important to us. It gives us new perspectives, strengthens our business and contributes to our development going forward.

Image to the left: Anesa Gacic, Josefine Lange and Ellinor Andersson, worked on a project in Sustainable Production Development, together with our site in Garphyttan during the fall of 2024. They are three driven students from Örebro University – who are pursuing a Master of Science in Industrial Engineering and Management.

Voices from our organization and our collaboration partners >>> What does personal development mean to you?

Ulf Quadflieg

Business Area Manager EMEA, Düsseldorf, Germany

"Personal development comes along with lifelong learning when finding yourself in challenging situations, both in the job and private life. This ever-changing world offers so many opportunities and this is what keeps me engaged and brings fun and spice to my life."

Dave Rogers

Quality & Engineering Manager, South Bend, US

"I believe personal development starts with a vision and a shared goal. When we have clear directions, our teams provide the knowledge and tools to help us move forward. We bring plans to life. Being part of this collaboration is both engaging and exciting."

Thomas Rasmusson

Operations Manager, Tegelbruket in Örebro, Sweden

"Together with Suzuki Garphyttan and other partners, we give young people from diverse backgrounds the opportunity to grow both their interests and as individuals. Through our collaboration, we help them on their way into the job market and provide them with tools for the future."

Digitalization

Successful launch in Mexico

In 2024, Suzuki Garphyttan’s site in San José Iturbide, Mexico, successfully implemented the OneShare business system. Implementation has thus been completed in Sweden, Germany and Mexico.