Why choose Suzuki Garphyttan steel wire for liftspring production

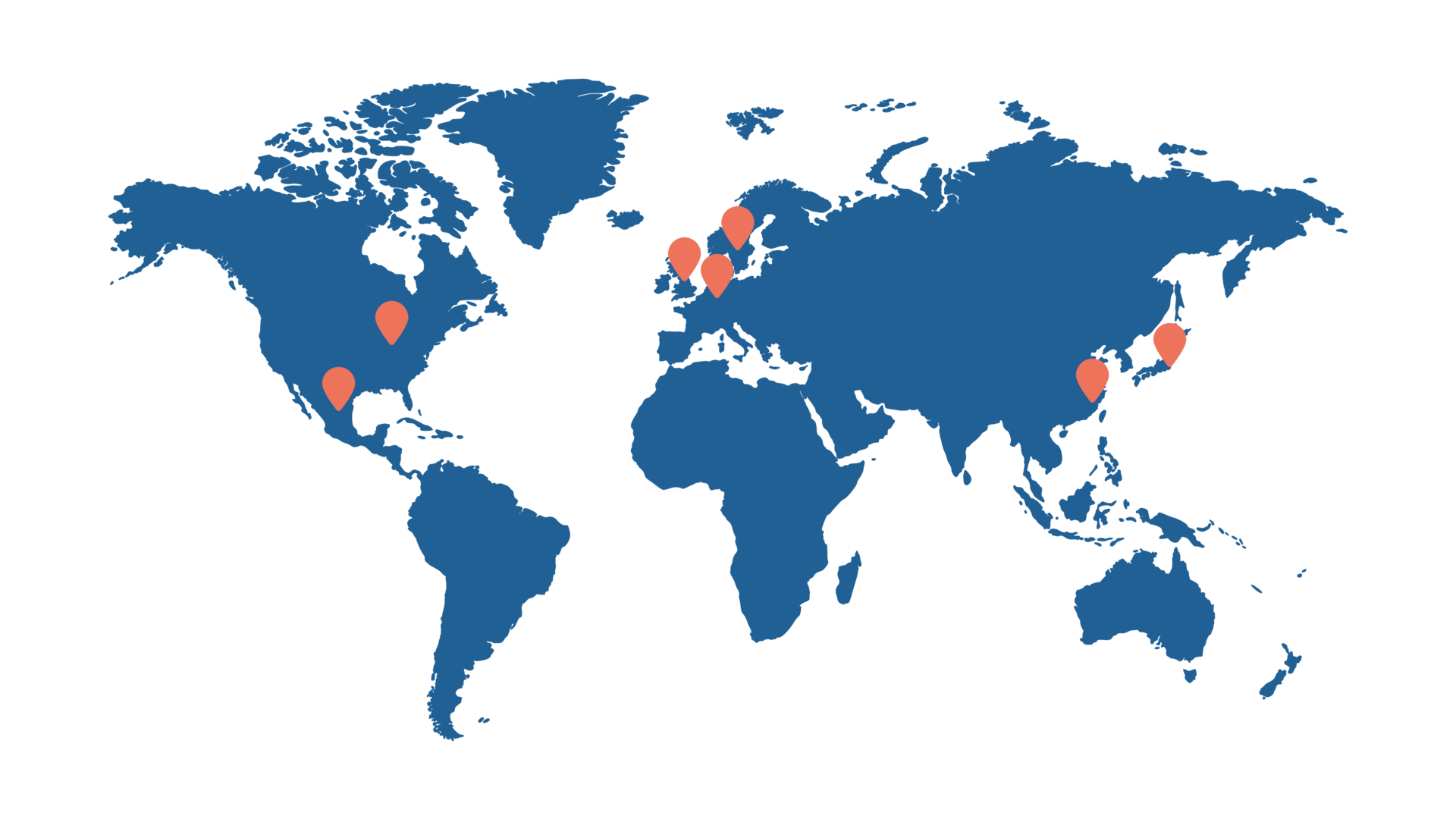

Our commitment to consistent quality, customizability, and industry-focused solutions make us the trusted choice of leading lift spring manufacturers worldwide. With decades of experience in the steel wire industry, we have honed our manufacturing process to produce steel wire that is not only strong and durable but also customizable to specific applications. Our wire for Powergate Liftspring is a testament to this expertise.

Our steel wire's high tensile strength ensures that the spring can withstand heavy loads, while its excellent fatigue resistance guarantees a high number of cycles without performance degradation. Moreover, the customizability of our steel wire allows manufacturers to fine-tune the spring specifications to their unique needs.

At Suzuki Garphyttan, we go the extra mile to ensure quality. Our production process is backed by rigorous quality control procedures and industry-leading certifications, ensuring that the steel wire you receive from us is of unwavering quality, offering consistent performance in liftspring manufacturing.

Power back door manufacturing with Suzuki Garphyttan steel wire

- Our steel wire complies with globally recognized standards, assuring you of its high quality and reliability.

- We offer a broad size range of steel wire, catering to various lift spring designs and applications.

- Our high-grade steel wire contributes to enhanced yield, reduced downtime, and minimized scrap in your manufacturing process.