Elevate your wave spring production with Suzuki Garphyttan's tailored wire solutions

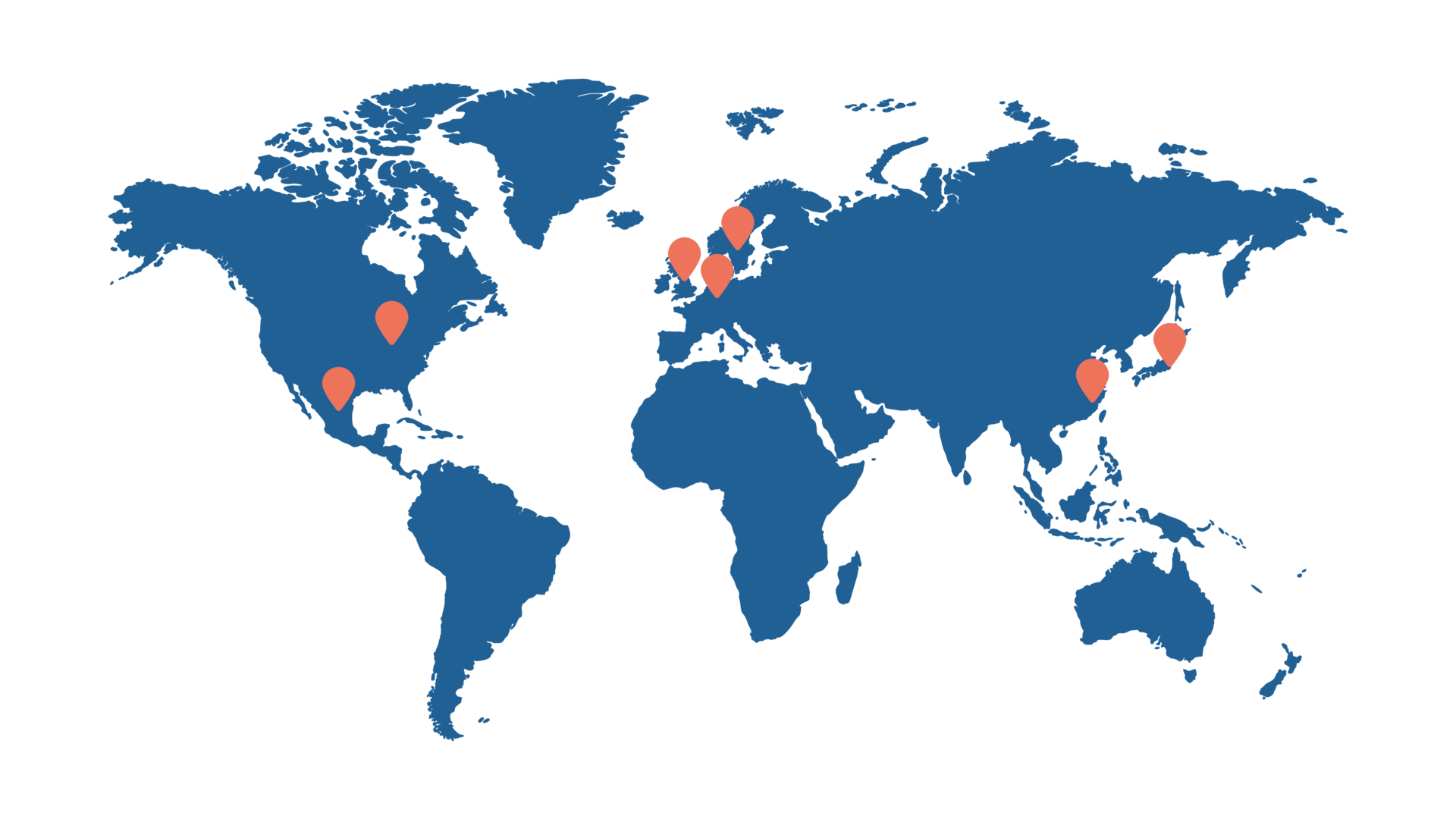

As a global supplyer of steel wire solutions for high-performance applications like Wave Springs, Suzuki Garphyttan leverages a century of expertise, advanced technologies, and different production practices to meet industry-specific needs. Our relentless pursuit of innovation and our commitment to closely working with our customers ensures we are at the forefront of shaping the wire solutions of tomorrow.

Our wire for wave springs

- Superior tensile strength and fatigue resistance, fortifying wave springs against heavy loads, high temperatures and ensure high numbers of cycles.

- Customization capabilities that empower manufacturers to fine-tune wire specifications to their unique needs.

- Quality and performance, assuring dependable and enduring wave springs.

- High-grade material and compliance with international standards.

- Broad size range.

- Unwavering quality, with excellent straightness.

- Production flexibility and order quantity.